Are you considering printing garments? If so, then there are two options. These are DTG and screen printing, and you need to know the difference between them before you begin.

Both have a number of advantages and disadvantages to consider. Below we discuss screen printing and direct-to-garment printing to help you decide the best fit for your project.

What Is Screen Printing?

Screen printing is a process used to apply designs to fabric. It uses a woven screen named a mesh stencil, through which ink is pushed. This ink then lays on top of fabric and sets, creating the final design.

Each element of your design requires a new screen to be set up. The various colors and shapes are placed on the fabric layer by layer. This is then pushed through the layer using a blade or foam tool.

Screen-printed designs are usually made from many of these layers. Due to this, complex designs will take longer to print and have thicker layers on the fabric.

Screen Printing Pros and Cons

Screen printing allows you to have extremely bold colors. As they are layered one on top of another, this makes them extremely durable. They are great for long-lasting, vivid designs.

The downside of screen printing is that it takes a long time to set up. If you have intricate designs and many colors, this takes even longer. With complicated designs, you may also find that the many layers create a heavy, thick print that some may find uncomfortable.

What Is Direct to Garment?

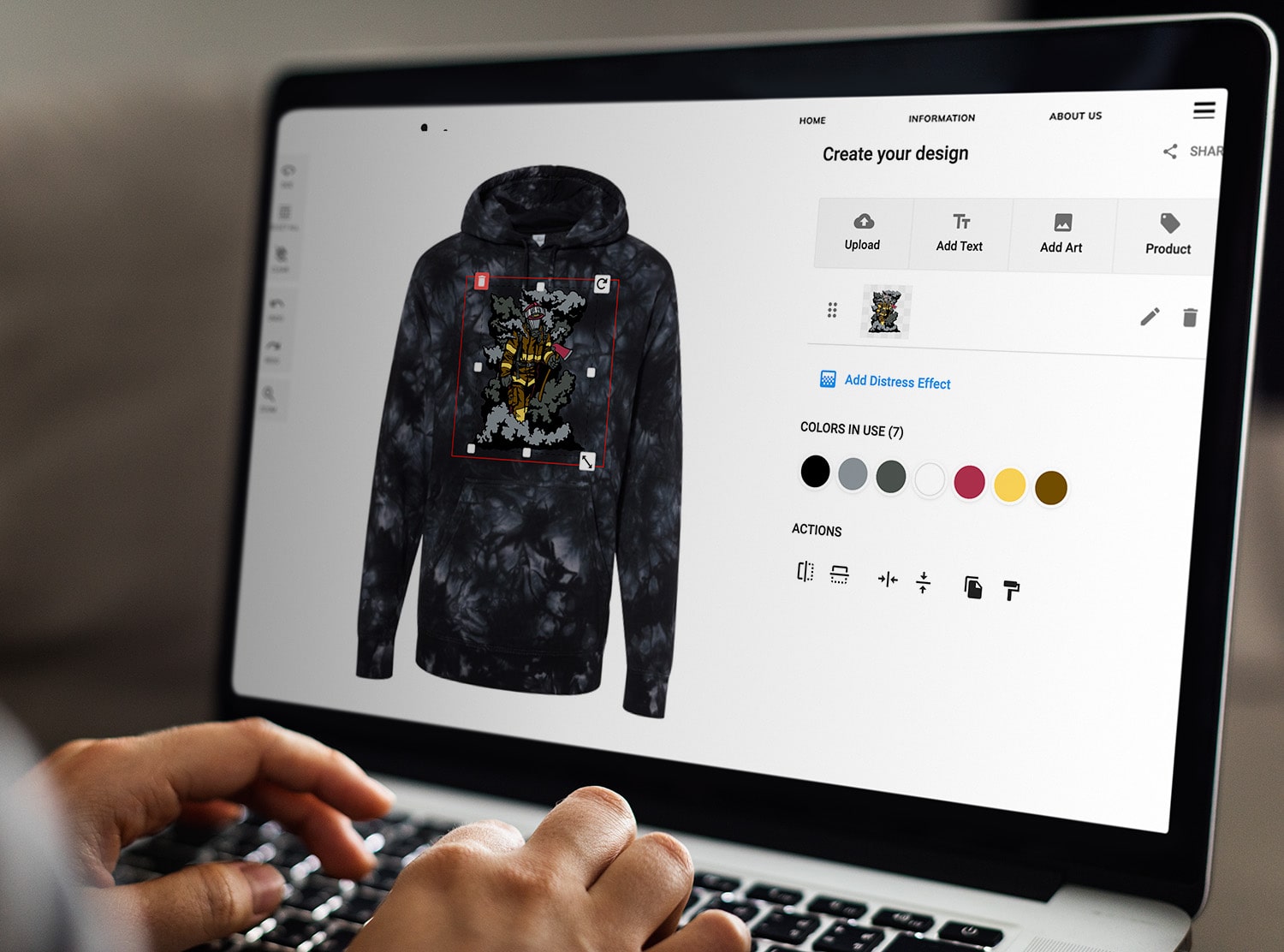

Direct to garment (DTG) is a modern printing method, in which ink is sprayed onto the fabric. It uses technology very similar to a printer that you would find in a home or office. This allows it to make very precise designs.

Unlike screen printing where the ink sits on top, in DTG printing the ink soaks into the fabrics. It is extremely fast and requires very little set up time.

Direct to Garment Pros and Cons

Direct to garment uses a thin layer of ink to create your images. This means it does not have a heavy, built-up feel that you may get with screen printed garments. Because of this, it has no color limitations like you get in screen printing.

The cons are that colors can sometimes lack the boldness of screen printing. Designs will also be less durable, as they are only made from a single layer of ink. This may also have an impact when you try to apply light colors onto dark fabrics, so you should test this before committing to order or design.

Should I Use Screen Printing or Direct to Garment for My Design?

When considering which you will use, consider the design you are printing. Both screen and DTG printing have advantages and cons, depending on the design you use.

Screen printing is generally much better for a simple, solid design with few colors. Firstly, each layer takes a lot of setting up, so huge details and many colors will take an awful lot of time. You may find that many manufacturers will set a limit on the number of colors you can use.

DTG lets your use a huge range of colors, with a large amount of detail. If you create your image in the RGB color palette, you should be able to realize the whole spectrum on a shirt.

One drawback of DTG is transparent images. Any colors that run at less than 100% opaque do not come out well. Printers will try to fill in the gaps by spreading the colors, which gives a disjointed finish.

Ecological Consideration of Screen Printing vs Direct to Garment

As screen printing takes a lot of set up, you usually find that many people over order. This results in unwanted products that may not get sold and waste resources. In addition, some screen printing uses inks that do not degrade.

As DTG allows you to produce as many or as few products as you like, it generally results in less waste. They can use a range of inks, many of which are water-based. In addition, they often use modern technology that is designed with sustainability in mind.

Screen Printing vs Direct to Garment Cost

Unless you order in large amounts, screen printing is not really worth the cost. It requires a lot of work to set up the mesh required for each layer of design. However, once you pass a certain threshold the cost for screen printing becomes very economical, as you are only paying for the labor and materials.

If you use fewer colors and more simple designs, it brings the cost down considerably. You can create master stencils which will speed up the process as you create more.

If you are using a wide range of colors in small batches, then DTG printing is more cost-effective. You will not be charged extra for more colors or the intricacy of the design.

When you start to order in bulk, it becomes less effective. Machines can only print one t-shirt at a time, and if you have many colors and designs this will take time. This means no bulk saving for large orders unless you can reach a deal with the printer.

Discuss With a Professional

If you still can not decide, speak with a professional. Many companies offer both screen printing and DTG printing. They can help work out which will be best for you or even make a combination.

Discover Tee should be your first stop when looking for garment printing. We have a range of options to suit all your needs. Click here for a quote, and let us help create your next high-quality product starting today.